This has increased the speed and accuracy of calculations and reduced the time required to complete the process. Automated systems can quickly process data and generate reports, reducing the likelihood of errors and saving time. As mentioned earlier, outsourcing production can increase transportation costs. This can be a significant expense if the outsourcing company is far from the contract manufacturer. Additionally, outsourcing may increase the risk of product damage during transportation, impacting conversion costs. Materials costs can fluctuate based on factors such as changes in commodity prices or supplier costs.

Reduced Investment in Equipment – How Does Outsourcing Impact Conversion Cost?

- For instance, in an automobile assembly line, the wages of assembly line workers and machine operators constitute direct labor costs.

- A periodical review of the firm’s prime cost is crucial to ensure the efficiency of its manufacturing process.

- The labor hours can then be multiplied by the hourly rate to determine the direct labor cost.

- Understanding and optimizing conversion costs enable businesses to make informed decisions about pricing, budgeting, and resource allocation.

By optimizing the landing page design, simplifying the checkout process, and adding customer testimonials, they reduce bounce rates by 20% and increase conversions by 15%. Total Conversion Cost refers to the overall expenses incurred during the process of converting leads or prospects into paying customers. It encompasses various elements that contribute to the financial investment required to achieve successful conversions. So, sit back and ledger account read on to better understand conversion cost in accounting and how it affects your business. Training employees to enhance productivity and minimize errors can reduce labor-related costs. Keep the pages simple, so viewers are more likely to perform the action you want.

Examples of Conversion Costs

- Direct expenses are costs directly traced to a particular product or process.

- Prime costs are expenditures directly related to creating finished products, while conversion costs are expenses incurred when turning raw materials into a product.

- It helps in making informed decisions regarding process optimization, cost reduction, and pricing strategies.

- See this article from Forbes that explains the difference among cost, worth, and value to learn more.

- Examining prime costs helps optimize material expenses through strategic sourcing and inventory management.

- Automation can have a significant impact on conversion costs in manufacturing.

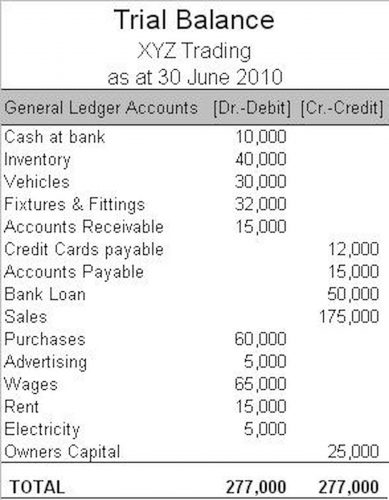

In this section, we will explain conversion costs how to calculate conversion cost per unit and how to use it for different purposes. We will also provide some examples and insights from different perspectives. Conversion cost is a vital metric for manufacturing and production businesses. It includes direct labor costs and manufacturing overhead costs, which are necessary to transform raw materials into finished goods.

How to Calculate Conversion Cost

Production processes vary depending on product complexity, batch size, and equipment. These variations can impact the time and resources required to produce a product, affecting the calculation of conversion costs. Understanding the conversion cost is crucial for managing cash flow effectively. By knowing the total cost of production, manufacturers can accurately forecast their expenses and plan accordingly.

By understanding, managing, and optimizing these costs, organizations can enhance efficiency, maintain quality, and stay competitive in the market. Remember that direct labor costs are not just numbers; they represent the hard work and dedication of the people behind every product or service. Yes, conversion costs are relevant for decision-making in a manufacturing business. These costs are directly related to the production process and AI in Accounting can impact the company’s overall profitability. Therefore, managers must consider conversion costs when pricing, production volumes, product mix, and outsourcing. Technology has made it easier for different departments within a company to communicate with each other about conversion costs.

Zero Defects: Achieving Perfection in Quality and Manufacturing

In summary, direct material costs are fundamental to production and require strategic management. By understanding their nuances, businesses can optimize costs, enhance product quality, and maintain competitiveness. Remember, these costs are not just numbers; they represent the tangible building blocks of every product we encounter in our daily lives. The calculator will then present the total conversion cost, which is the sum of the direct labor cost and the manufacturing overhead. Standard costing involves estimating the cost of producing a product before actual production begins.